B-2.2 Installation of Heating and Cooling Sources

Regardless of whether a building is being newly constructed or a renovation is planned, you must be familiar with all documents that specify the minimum system requirements. This may include the manufacturer’s installation instructions and specifications as well as all pertinent codes, regulations, and standards.

Equipment Inspection Before Installation

Heating and cooling equipment may be damaged during shipping from the factory to its final destination, where it is to be installed. When equipment arrives on site, it is important to visually check the equipment (if possible) and packaging for damage. Damaged packaging may indicate internal damage, even if the outside surfaces seem unaffected. Internal parts may be cracked, broken, or shifted out of alignment.

If equipment with unnoticed deficiencies is installed, two issues arise:

- The equipment must now be either fixed or replaced, costing the installer money.

- It becomes harder to identify when the equipment was damaged.

If you suspect damage of any type, be sure to take pictures, make notes, and notify the appropriate parties involved. It is also a good idea to have an impartial third party witness the unpacking of the equipment to be able to verify that the equipment was in fact damaged before installation.

Codes and Regulations

All heating equipment must be installed according to the codes and regulations specified by the region in which they are installed. The Canadian Standards Association (CSA) B214 Code is the Installation Code for Hydronic Heating Systems in Canada. This code covers many different areas of hydronic heating installations, including heating equipment. Section 5 covers heating equipment, and within this section, references are made to other standards that may have more specific installation guidelines. For example, Clause 5.2.1 of the B214 specifies that all gas-fired equipment and installations shall be installed in accordance with the B149.1 code, while Clause 5.2.5 indicates that all solar heating installations shall be installed in accordance with CSA F379 series and CAN/CSA-F383.

The person installing heating equipment may have to reference more than one code. For example, boilers must meet requirements of the applicable boiler and pressure vessel regulations as well as requirements found in boiler, building, plumbing, electrical, gas, and fire codes.

Codes and regulations that may specifically apply to the boiler may include:

- ASME Boiler and Pressure Vessel Code

- Canadian Gas Code (CSA B149)

- Power Engineers, Boiler, Pressure Vessel and Refrigeration Safety Regulation

- CSA Standard B51 (the Boiler, Pressure Vessel and Pressure Piping Code)

- The Institute of Boiler and Radiator Manufacturers (IBR)

- Fire Marshalls Act of BC

- National Fire Protection Association (NFPA)

Although codes are similar throughout the province and across Canada, they frequently change to reflect new and specialized equipment, changes in safety practices, and previously unidentified hazards. Before installing a boiler or other equipment, installers must be familiar with code requirements and local by-laws that may affect installation.

It is also important to consult the authority having jurisdiction (AHJ). The AHJ will use the codes and regulations as a guideline but may also require the installer to comply with more region-specific installation practices.

The AHJ also issues installation permits. Contractors are required to apply for an installation permit before doing the work. For every installation permit, there must be an inspection of the installation by the designated AHJ. For large commercial applications, an occupancy permit is required, and it is issued after inspection by the fire marshal and building inspection authority.

In all cases, it is important to follow the manufacturers’ installation literature and specifications when installing any equipment. Note that that the literature that accompanies the equipment is certified along with the equipment.

Not following the manufacturers’ installation specifications may void the warranty and cause damage and personal injury. In most situations, the manufacturers’ installation specifications, the authority having jurisdiction, and the codes and regulations are fairly harmonized.

Layout

The installer must always consider the location of the heating and cooling equipment when installing it. When laying out the installation, the installer must consider supply of power, water, fuel, and air, as well as equipment clearances and venting requirements when deciding where to locate the heating and cooling equipment.

Clearances and Access

Understanding the equipment clearances required will help the installer to get a better picture of the layout of the equipment. Installation clearances are specified by both the manufacturer and the specific installation code that governs the equipment, and they are important for two main reasons. One is to ensure necessary access to all parts of the equipment during installation and later when the equipment may need servicing. Insufficient space for service access will undoubtedly create problems. This applies to both the equipment itself and the general area where the equipment is installed, such as a crawl space or mechanical room.

The other main consideration when installing equipment is clearances to combustibles. All appliances have clearances listed on their rating plates as well as in the manufacturers’ literature, and these clearances must be observed to guarantee a safe operating situation in regard to fire prevention.

Section 7.1 of the B149 Gas Installation Code specifies minimum boiler clearances from combustible materials as:

- Vertical: 45 cm (18 in.)

- Sides and rear: 45 cm (18 in.)

- Front: 120 cm (48 in.)

Always check the manufacturers’ instructions and use the most restrictive clearances.

Electrical Connections

While gasfitters may be permitted to work on some aspects of the electrical system associated with a gas heating system, a certified electrician working for an electrical contractor will often be involved in any electrical work.

The Canadian Electrical Code states that all heating equipment must have a dedicated branch circuit. This means that a 120-volt circuit from the breaker panel must only serve one source of heating equipment. The intent is to limit the possibility that other items sharing such a circuit might have a negative effect on the operation of the heating equipment, which during the colder winter months could prove disruptive at best. A qualified gasfitter with an electrical endorsement may perform electrical work from the wall disconnect switch to the gas appliance but may not install the branch circuit itself; this is the work of an electrical contractor.

Water Supply and Fuel Supply

All hydronic equipment requires both fuel and water to function properly. When installing hydronic equipment, make sure that both are readily available and relatively easy to incorporate into the system. Although this may sound fairly logical, oftentimes getting fuel or water to the heating and cooling equipment can be more challenging than it seems.

The water source used to supply the equipment is going to be the same water source that is used to supply the domestic water for the building. The water that is used to fill the hydronic system must not be allowed to come back into the domestic potable water system. If that happens, the best case scenario would be aesthetically unpleasing water (taste, appearance and odour) created by stagnation or leaching of metals; the worst one would be death caused by chemical additives. Makeup water must be supplied through a backflow preventer to maintain the integrity of the building’s potable water system.

The main issue regarding the fuel supply is availability. British Columbia’s natural gas transmission pipelines service much of the province, but many areas are still out of reach, and other fuels (e.g., propane, fuel oil, and electricity) and forms of solid fuel (e.g., wood) must be used. Always make sure that the equipment being installed works with the fuel sources available.

Air Requirements and Venting

All hydrocarbon fuel sources require air for the combustion process. Allowing for an adequate source of air ensures proper combustion and, ultimately, that the heating or cooling equipment operates in a safe manner. The air used for the combustion process must come from a permanent air intake directly from the outdoors and must not be taken from a carport or temporary intake, such as a window into a mechanical room, which could limit or negate the air supply if closed.

Section 8 of the B149.1 Natural Gas and Propane Installation Code sets the requirements for both combustion air supply and venting requirements for gas-fuelled appliances.

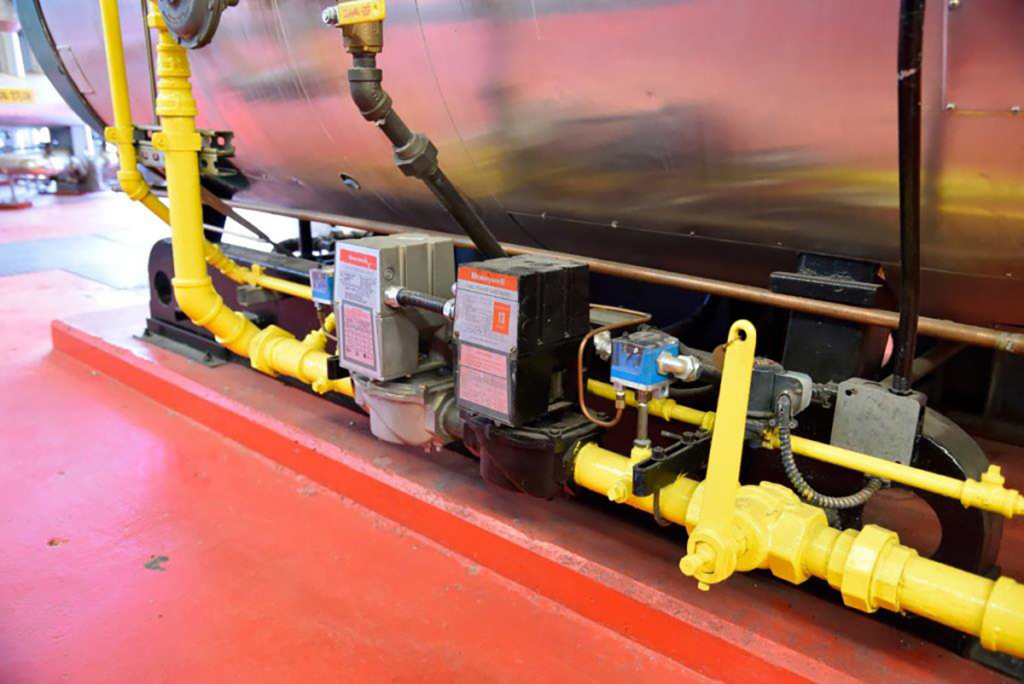

Housekeeping Pads

Section 7.1 of the B149.1 Natural Gas and Propane Installation Code requires that a gas boiler shall conform to the requirements of the provincial boiler and pressure vessel regulations as applicable. Section 7.1 also states that a boiler shall be installed on a firm and level base, which can include housekeeping pads; this requirement is consistent with the other applicable codes.

A housekeeping pad (Figure 1) is a raised concrete platform on which the boiler is mounted. It minimizes the possibility of dust, dirt, or other litter that might be on the mechanical room floor being swept under or into the boiler. It also elevates the boiler above any water that might be on the floor that could corrode the boiler’s frame.

Self-Test B-2.2: Installation of Heating and Cooling Sources

Self-Test B-2.2: Installation of Heating and Cooling Sources

Complete the chapter Self-Test B-2.2 and check your answers.

If you are using a printed copy, please find Self-Test B-2.2 and Answer Key at the end of this section. If you prefer, you can scan the QR code with your digital device to go directly to the interactive Self-Test.

References

Skilled Trades BC. (2021). Book 1: Fuel gas systems, heating and cooling systems. Plumber apprenticeship program level 2 book 1 Harmonized. Crown Publications: King’s Printer for British Columbia.

Trades Training BC. (2021). B-2: Describe hydronic heating and cooling generating equipment. In: Plumber Apprenticeship Program: Level 2. Industry Training Authority, BC.

Media Attributions

All figures are used with permission from Skilled Trades BC (2021) unless otherwise noted.

An organization or person responsible for enforcing safety and building codes. They make sure that buildings and structures follow the law and safety standards, such as proper electrical wiring and fire safety measures. (Section B-2.2)

An electrical circuit that supplies power to only one specific piece of equipment or appliance, without sharing the circuit with other devices. (Section B-2.2)

A water supply system that provides water safe for drinking and other domestic uses, free from harmful contaminants. (Section B-2.2)

A device that stops water from flowing backward into the water supply. It ensures that water doesn't get contaminated by preventing dirty or used water from flowing back into clean water lines. (Section B-4.2)

A raised concrete platform on which mechanical equipment, such as a boiler, is mounted. (Section B-2.2)